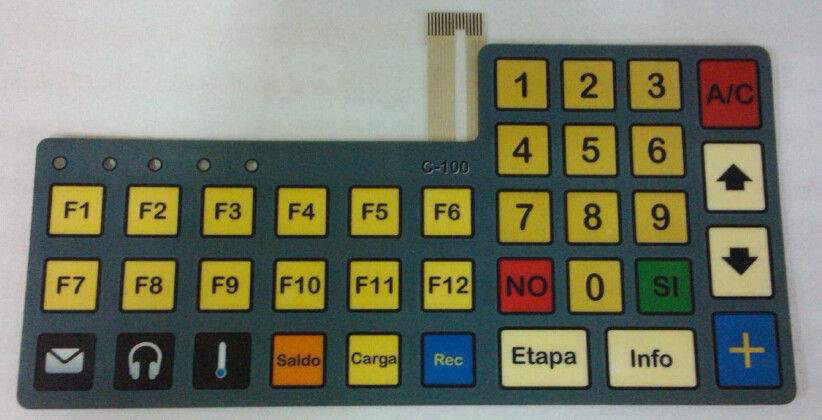

Polyester Silk Printed Tactile Flexibile Membrane Switch Keyboard For Mobile Phone

-

Menyoroti

custom membrane switch

,membrane touch switch

-

MaterialAutotex

-

Colorany color, color printing, digital printing

-

DomeMetal or poly

-

PINPIN with connector

-

Tempat asalCina

-

Nama merekTKM MS

-

SertifikasiISO9001:2008, SGS,Rohs

-

Model NumberTKM-MS-383

-

Minimum Order Quantity1X pcs

-

Harganegotiable

-

Packaging DetailsPolybag per pcs,50per cartoon

-

Delivery Time15-20days

-

Payment TermsT/T or , Western Union

-

Supply Ability100000Pieces per month

Polyester Silk Printed Tactile Flexibile Membrane Switch Keyboard For Mobile Phone

Silk Printed Keyboard Membrane Switch Keyboard 100MΩ 250V DC

Quike Detailes:

1. Flexibility

It can be bent, folded and deformed freely. Its coil radius is small and it can be moved freely along X, Y, Z axis separately.

2. Occupy small space

Since it is light and thin, it makes best use of the narrow space in the instruments. (average thickness 1.1-0. Am)

3. Light weight

Its weight is very light because the design of FPC is not based on mechanical strength but current load.

4. Good seal capability

The flexible board could be designed for low- tensile seal enduring the adverse environment.

5. Steady transmission

The wiring pattern and the conductor distance can be freely designed according to electric parameters. Once the pattern is finalized, parameters of R. L. C is steady accordingly.

6. Easy assembly

The property of terminal is good enough to be fixed to any equipment by soldering, inserting, riveting and gluing. Manual mistakes in traditional wiring are avoided.

7. Good insulation

We selected the materials with good insulation property, such as polyimide, polyester, etc. Usually, the wiring is covered, so the insulation is greatly strengthened.

FPC & FFC can be extensively applied:

Description:

Copper foil substrate (Copper Film) [3]

Copper foil: basically divided into two kinds of electrolytic copper and rolled copper common thickness 1oz 1/2oz and 1/3 oz

Substrate film: a common thickness of the 1mil with 1/2mil two kinds.

Glue (adhesive): thickness according to customer requirements.

Cover film protection film (Cover Film)

Cover film protection film: surface insulation. The common thickness 1mil with 1/2mil.

Glue (adhesive): thickness according to customer requirements.

Adhesive buildup of foreign matter before pressing the shape from the paper: avoid; easy job.

Stiffener (PI Stiffener Film)

Stiffener: reinforcing the mechanical strength of the FPC, to facilitate the surface mounting job. Common thickness 3mil to 9mil.

Applications:

1.The mobile phone

Focuses on the flexible circuit board light weight and thin thickness. Can effectively save the volume of products, easy connection of the battery, microphone, and buttons and into one.

2.Computer and LCD screen

Use the one line configuration of flexible circuit boards, and thin thickness. The digital signal into the picture, through the LCD screen

3.CD player

Focuses on three dimensional assembly characteristics of flexible circuit boards and thin thickness. The huge CD to carry around

4.Disk drives

Regardless of the hard disk, or diskette, is very dependent on FPC high softness and thickness of the 0.1 mm slim, read data finish quickly. Either a PC or NOTEBOOK.

5.The latest applications

Hard disk drives (HDDS, hard disk drive) of suspended circuit (Su ensi. N cireuit) and the components of xe packaging board, etc

Specifications:

| OEM/OEM | As per request |

| Material: | PI: 1 mil Cu: 1 oz PI: 1 mil |

| Surface treatment: | pure-tin plating |

| Minimum hole dimension: | 0.3mm |

| Minimum linear width: | 0.08mm |

| Minimum linear distance: |

0.08mm |

| External tolerance: | +/-0.05mm |

| Chemical resistance: | meet IPC standard |

| Bandability: | meet IPC standard |

| Surface resistivity: | 1.0 x 1011 |

| Heat resistance: | -200 to +300 degrees C |

| Peeling Strength: | 1.2kg/cm2 |

| Welding resistance: | 280 more than 10 seconds |

Competitive Advantage:

1.short: assemble shorter working hours

All lines in the configuration is complete. Save extra FPC PCB FPC PCB wiring connection work

2. Small: small volume PCB

Can effectively reduce the products volume. The increase is to carry on the convenience

3. Light: weight lighter than PCB (hard)

Can reduce the weight of the final product

4.Thin: thinner than the thickness of hard PCB board.

Can improve the softness. Strengthen then limited space for three dimensional assembly

5.quick delivery

6.best services